16 September 2025

The global artificial grass market is experiencing robust growth, driven by increasing demand for sustainable, low-maintenance, and aesthetically pleasing landscaping solutions across various sectors. From sprawling sports fields to intricate indoor designs, the versatility of wholesale grass carpet has transformed how businesses approach ground cover and aesthetic appeal. This evolution is particularly evident in the commercial and recreational segments, where products like an area rug that looks like grass or even artificial grass bedroom carpet are gaining traction for their unique blend of functionality and visual charm. As a leading manufacturer and supplier, we recognize the critical need for high-quality, durable, and cost-effective artificial turf solutions that meet stringent B2B specifications and deliver long-term value.

The industry trend indicates a shift towards advanced synthetic fibers and backing materials, enhancing product longevity, UV resistance, and drainage capabilities. This technological progression allows for broader applications, from artificial garden mat installations in urban green spaces to specialized artificial grass aisle runner for events and retail. Our commitment lies in providing innovative artificial carpet solutions that not only replicate the natural look and feel of grass but also offer superior performance characteristics, contributing to environmental sustainability through water conservation and reduced chemical use.

At the forefront of our product line is Carpet Grass CG15, a testament to advanced engineering in synthetic turf technology. The CG15 is meticulously designed to elevate both sports performance and visual effects, simultaneously boosting durability and stability through a sophisticated upgrade in the height and density of its grass fibers. This particular artificial carpet variant is not merely an aesthetic choice; it’s a performance-driven solution engineered for high-traffic areas and demanding environments, where resilience and consistent playability are paramount.

CG15's enhanced fiber structure, typically featuring a blend of polyethylene (PE) and polypropylene (PP) monofilaments, ensures an optimal balance of softness and spring-back recovery. This makes it an ideal choice for a diverse array of applications where a premium artificial grass carpet is required. Its robust construction minimizes wear and tear, reducing the frequency of replacement and offering a superior return on investment for businesses seeking long-term solutions for their outdoor or indoor spaces.

Understanding the technical specifications is crucial for B2B procurement decisions. Our artificial carpet products, including the advanced CG15, are designed with precise parameters to ensure peak performance and longevity. The table below outlines key technical characteristics, providing a clear comparison of general artificial grass types with our specialized Carpet Grass CG15, highlighting its superior build quality.

Artificial Grass Technical Specifications Comparison | ||

Parameter | Standard Artificial Grass | Carpet Grass CG15 (Premium) |

Fiber Material | PE or PE/PP Blend | High-grade PE Monofilament & PP Thatch |

Pile Height | 20-40 mm | 35-50 mm (Enhanced for sports/aesthetics) |

Density (Stitches/m²) | 10,000 – 16,000 | 18,000 – 22,000 (Higher for durability/feel) |

Dtex (Fiber Thickness) | 6,000 – 10,000 | 12,000 – 15,000 (Thicker for resilience) |

Gauge (Distance between rows) | 3/8", 5/8" | 3/8" (Optimized for density) |

Backing Material | SBR Latex or PP | Triple-layer Polyurethane (Superior adhesion/stability) |

UV Stability | Standard UV protection | Advanced UV inhibitors (8-10 year warranty) |

Fire Rating | Class Efl | Class Dfl (or better, per local standards) |

Drainage Rate | ~60 liters/min/m² | ~80-100 liters/min/m² (Enhanced for heavy rainfall) |

These specifications underscore the meticulous design and manufacturing behind our CG15 artificial grass carpet. The increased density and Dtex contribute directly to better wear resistance and a more natural, lush appearance, making it a premium choice for diverse applications, from high-end landscaping to robust athletic surfaces.

The production of high-quality wholesale grass carpet involves a sophisticated multi-stage manufacturing process, ensuring durability, aesthetic appeal, and performance. Our process adheres to stringent quality control standards, including ISO 9001 for quality management and ISO 14001 for environmental management, reflecting our commitment to both product excellence and sustainable practices. The primary stages typically include:

· Fiber Extrusion: High-grade virgin polymer pellets (polyethylene for blades, polypropylene for thatch) are melted and extruded into fine fibers, which are then stretched and texturized to mimic natural grass blades. UV stabilizers are integrated at this stage to prevent fading and degradation from sun exposure, ensuring the longevity of your artificial garden mat.

· Tufting: The extruded fibers are machine-stitched (tufted) into a primary backing material, typically a woven polypropylene fabric. This process creates the characteristic rows of grass blades. Precision tufting ensures uniform density and pile height, critical for the consistent feel and look of an area rug that looks like grass.

· Coating (Backing Application): A secondary backing, usually a robust polyurethane or SBR latex, is applied to the reverse side of the primary backing. This layer firmly locks the tufted fibers in place, providing dimensional stability, enhanced durability, and superior tuft bind strength. This is crucial for the structural integrity and lifespan of the artificial grass carpet.

· Perforation & Drying: The coated backing is perforated to create drainage holes, allowing water to pass through the turf, which is essential for outdoor installations. Following perforation, the entire product undergoes a drying and curing process to strengthen the backing adhesive.

· Quality Inspection & Packaging: Each roll undergoes rigorous quality checks, including pile height consistency, tuft bind strength, color uniformity, and overall dimensional stability. Products are then rolled and packaged for distribution. Our materials are also tested for REACH compliance, affirming their safety and environmental responsibility.

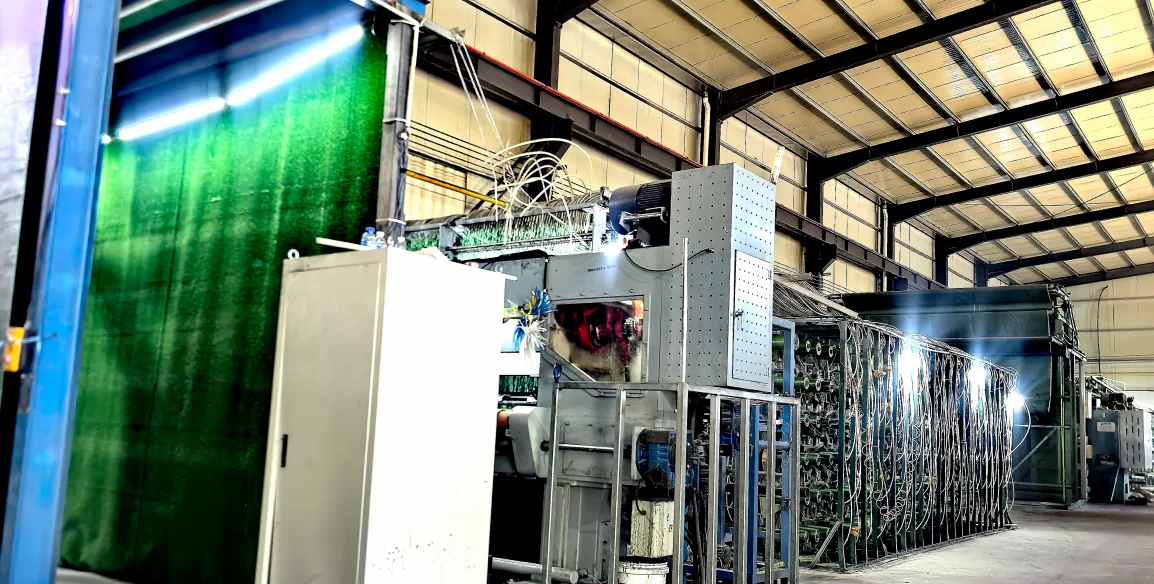

Fig 1: Illustrative overview of artificial grass production, highlighting precision manufacturing.

This meticulous process ensures that every square meter of our artificial carpet meets the highest standards of performance and aesthetics, suitable for demanding commercial and public applications. Our products offer a guaranteed lifespan, often exceeding 8-10 years, depending on traffic and maintenance, making them a sustainable and economical choice for businesses.

The adaptability of artificial grass makes it an indispensable asset across a multitude of industries. Our products, from wholesale grass carpet for large-scale projects to specialized artificial grass aisle runner for events, offer distinct advantages. For sports facilities, the Carpet Grass CG15, with its superior resilience and shock absorption, enhances player safety and optimizes performance, ensuring a consistent playing surface even under intensive use. This negates the need for constant watering, fertilizing, and mowing, translating into significant operational savings.

Beyond sports, our artificial garden mat finds extensive use in commercial landscaping, theme parks, hotels, and public spaces, providing lush green aesthetics without the demanding maintenance of natural turf. Residential applications are also growing, with options like an area rug that looks like grass or even artificial grass bedroom carpet adding unique textures and comfort to interior spaces. Key technical advantages include exceptional UV resistance (preventing fading), superior drainage systems (preventing waterlogging), and a non-toxic composition, making them safe for children and pets. This robust design also ensures anti-corrosion properties against environmental elements and offers notable water conservation benefits.

The global artificial turf market was valued at approximately USD 3.1 billion in 2022 and is projected to reach USD 5.2 billion by 2030, growing at a CAGR of 6.7%. This growth is largely fueled by increasing adoption in sports infrastructure and residential landscaping, highlighting the reliability and cost-efficiency of products like our artificial grass carpet. As market demands evolve, so does our capability to offer highly customized solutions. Businesses can specify variations in pile height, fiber color, density, and even unique shapes to perfectly match their project requirements.

Our expert team collaborates closely with B2B clients to develop bespoke artificial carpet designs, whether for a themed commercial display or a specialized sporting surface. This includes tailored infill recommendations for specific performance needs, such as enhanced shock absorption for playgrounds or optimal ball roll for putting greens. By providing flexible customization and technical consultation, we ensure that every client receives an artificial grass solution that is perfectly aligned with their operational goals and aesthetic vision, maximizing the lifespan and utility of their investment.

Fig 2: A modern office space utilizing artificial grass for interior design, showcasing aesthetic versatility.

We prioritize transparency and reliability in all our B2B engagements. Our comprehensive support system, from pre-sale consultation to after-sales service, is designed to instill confidence in our wholesale grass carpet offerings. We provide detailed information regarding delivery protocols, typical lead times (usually 2-4 weeks for standard orders, with custom projects varying), and robust quality assurance processes. Every batch of artificial carpet undergoes final inspection to meet internal standards and client specifications before dispatch.

Our products, including Carpet Grass CG15, come with an industry-leading warranty, typically ranging from 8 to 10 years, covering material defects and excessive UV degradation. This commitment underlines our confidence in the durability and longevity of our artificial grass carpet. Our dedicated customer support team is available to assist with technical queries, installation guidance, and any post-purchase concerns, ensuring a seamless experience for our B2B partners.

Q1: What is Dtex in artificial grass, and why is it important?

A: Dtex (decitex) is a unit of measurement for the linear mass density of fiber, representing the weight in grams of 10,000 meters of fiber. A higher Dtex generally indicates a thicker, more robust fiber, which contributes to increased durability, resilience, and a denser feel for the artificial carpet, particularly important for heavy-traffic areas.

Q2: What is the primary difference between PE and PP fibers?

A: Polyethylene (PE) fibers are softer and more pliable, making them ideal for the primary green blades, offering a natural feel. Polypropylene (PP) fibers are stiffer and more durable, often used for the thatch layer to provide cushioning and support, or in applications like an artificial garden mat where extreme resilience is needed.

Q3: What are the typical infill materials and their purposes?

A: Common infill materials include silica sand and crumb rubber (SBR or EPDM). Silica sand provides ballast and protects the backing, while crumb rubber enhances shock absorption, improves playability, and helps the blades stand upright. This is vital for the performance of artificial grass carpet in sports applications.

Q4: How does UV stability impact the lifespan of artificial grass?

A: UV stability refers to the grass's resistance to degradation from ultraviolet radiation. High-quality wholesale grass carpet incorporates advanced UV inhibitors during fiber extrusion, preventing fading, brittleness, and premature breakdown, thereby significantly extending its aesthetic and structural lifespan, especially in sunny climates.

Q5: What are the critical factors for proper artificial grass installation?

A: Key factors include proper sub-base preparation (ensuring compaction and drainage), accurate cutting and seaming of the turf rolls, correct infill application, and secure edging. Adhering to these standards ensures optimal performance, longevity, and a seamless finish for any area rug that looks like grass or larger installation.

Q6: Can artificial grass be recycled?

A: Modern artificial grass products are increasingly designed with recyclability in mind. While traditional latex-backed turf is challenging, newer polyurethane-backed systems and single-polymer products can often be recycled, separating the fibers from the backing for reuse in other applications, aligning with sustainable practices for artificial carpet waste management.

Q7: What are the fire safety standards for artificial turf?

A: Fire safety standards vary by region (e.g., ASTM, EN standards). Artificial grass products are typically rated based on their flammability and smoke emission. Our products generally meet or exceed Class Dfl fire ratings, ensuring they are designed to be fire-resistant and minimize flame spread, providing safety for installations like an artificial grass bedroom carpet or public areas.

1. Grand View Research. (2023). Artificial Turf Market Size, Share & Trends Analysis Report By Application (Sports, Leisure & Landscaping), By Raw Material (Polyethylene, Polypropylene, Nylon), By Region, And Segment Forecasts, 2023 – 2030.

2. ISO 9001:2015 – Quality management systems. (2015). International Organization for Standardization.

3. European Chemicals Agency (ECHA). (2024). REACH Regulation.

4. Synthetic Turf Council. (2023). Performance Guidelines for Synthetic Turf Sports Fields.

5. ASTM International. (2022). Standard Specification for Performance and Safety Requirements for Synthetic Turf Systems.

Hit enter to search or ESC to close